14 steps: from DNA damage to successful harvest

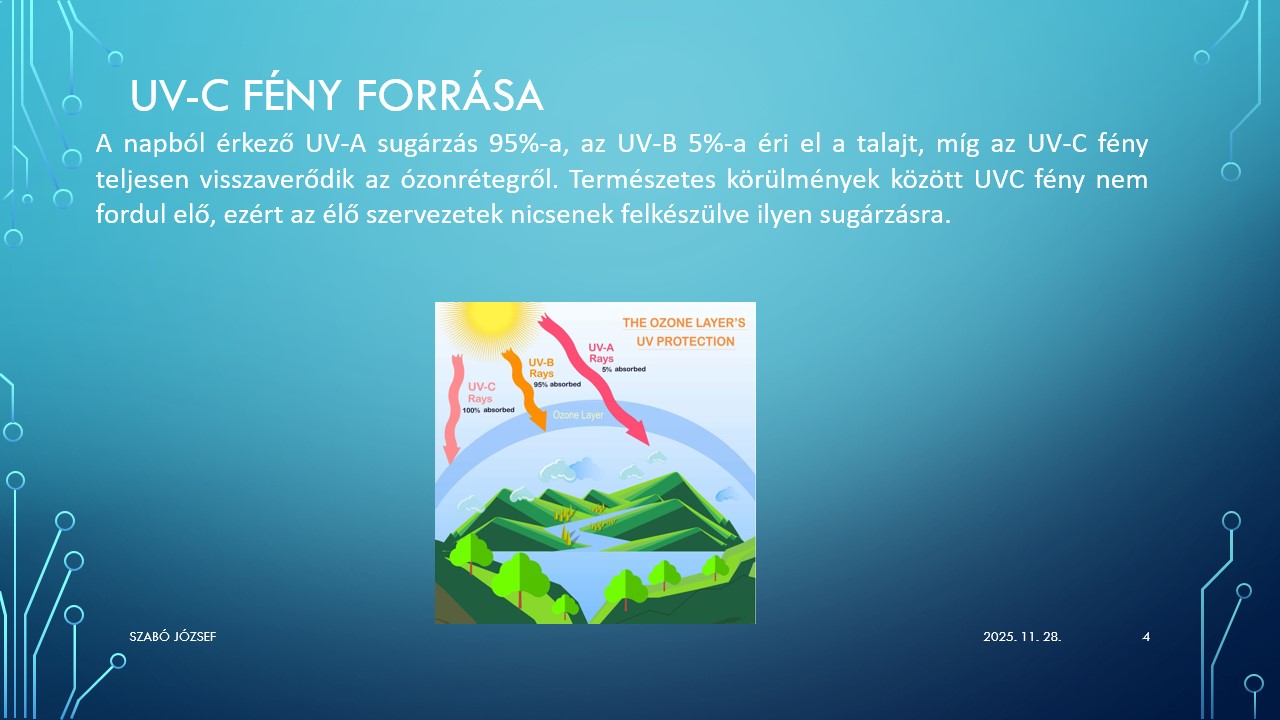

95% of UV-A and 5% of UV-B radiation from the sun reach the ground. UV-C (254 nm) does not penetrate the atmosphere, so we create it with artificial LEDs.

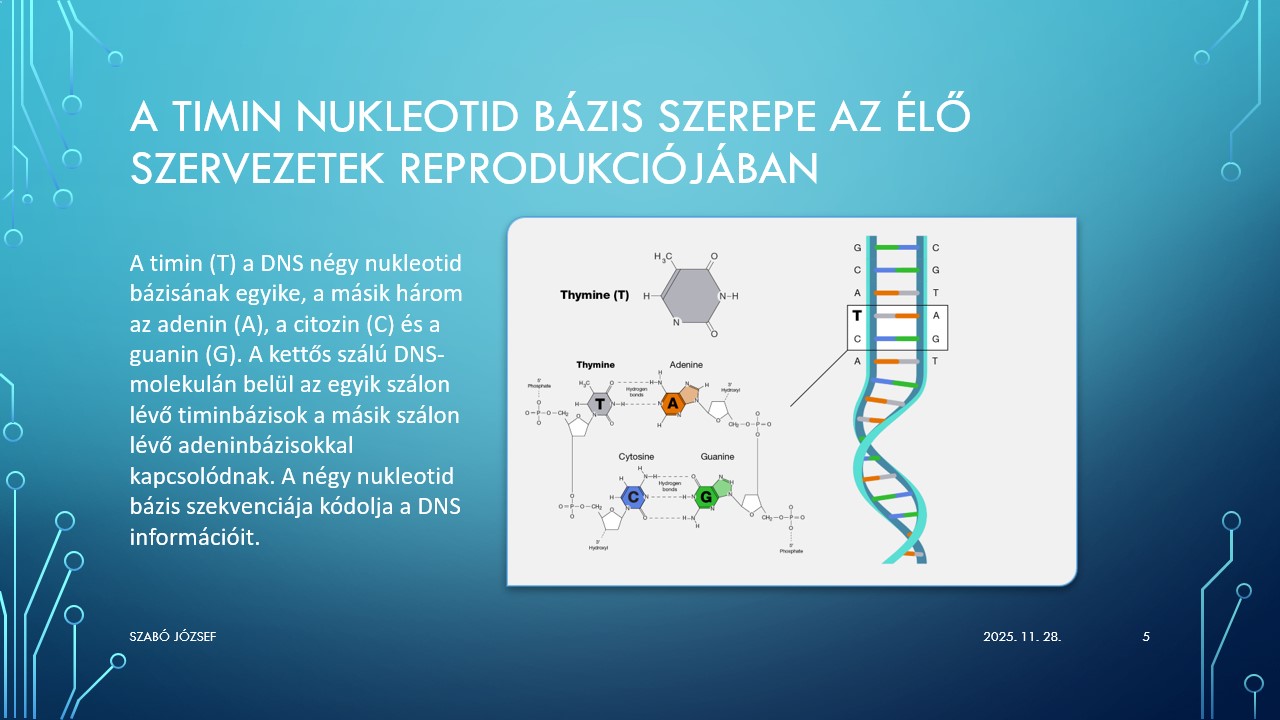

Thymine (T) is one of the four nucleotide bases of DNA (A, T, G, C). UV-C radiation directly attacks thymine, modifying chemical bonds.

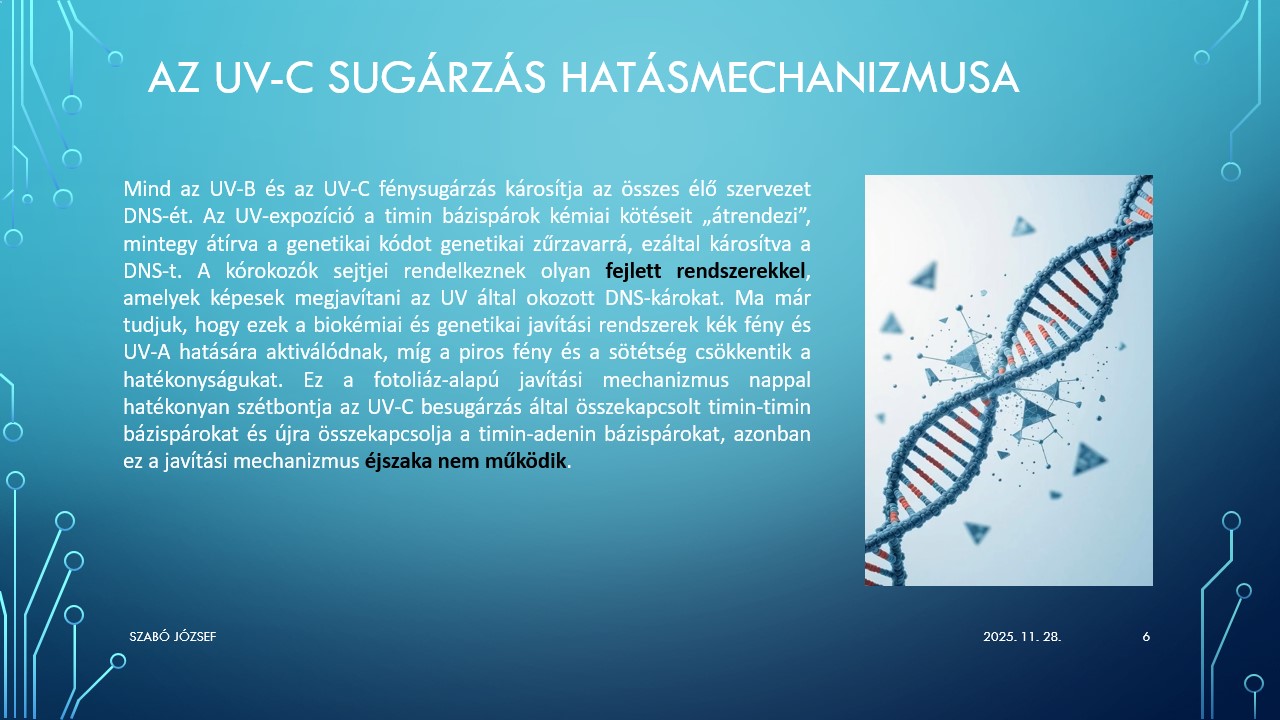

UV exposure dimerizes the chemical bonds of thymine base pairs, causing them to link together. This prevents DNA replication and cell division.

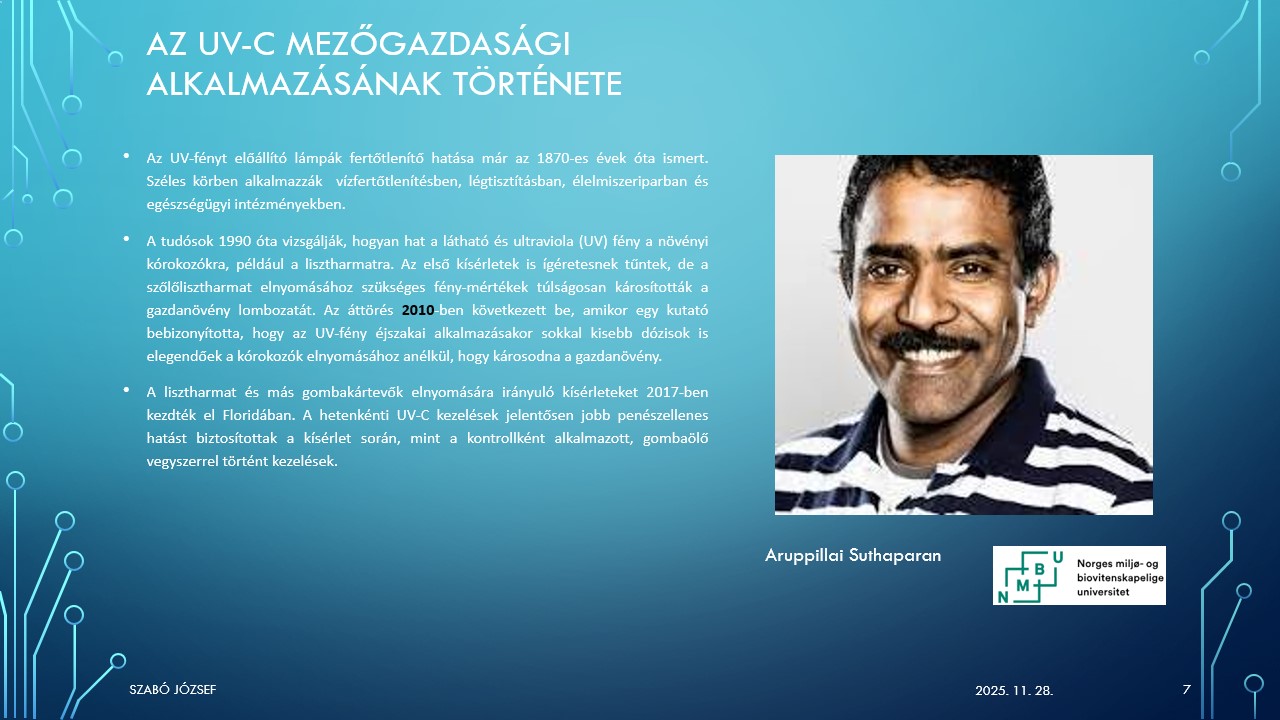

The disinfecting effect of UV-producing lamps has been known since the 1870s. The first research in viticulture began in the late 1990s at Cornell University.

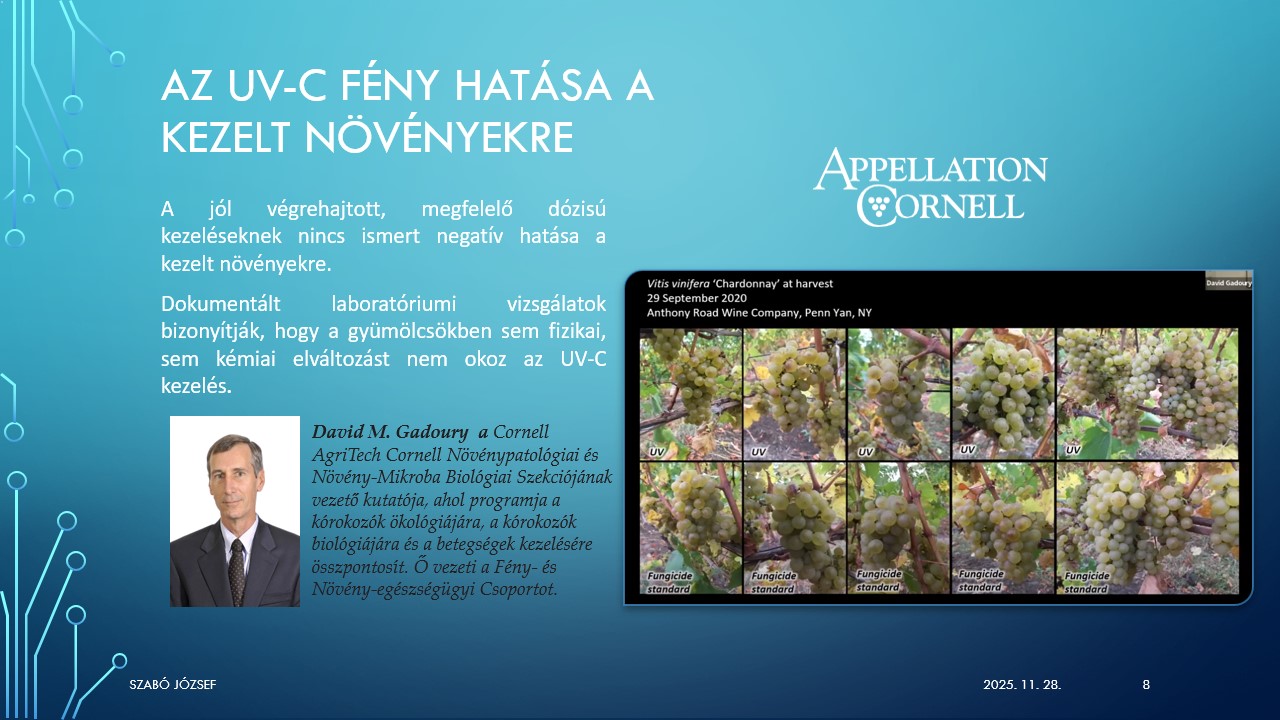

Properly dosed treatments have no known negative effects on grapes. Germinated UV-C even activates the immune system!

UV treatments can also suppress phytophagous mite populations (beneficial side effect!). However, UV-C is not toxic to beneficial insects.

Electric operation, 4 hours runtime, autonomous work. Fully automatic route planning and navigation. Operates with 50 cm row spacing.

UV-C LED fixtures developed by us. 254 nm wavelength, powerful, energy-efficient light sources.

Easily removable fixtures, 4-way adjustable light sources. Precise dose control. Optimized for vineyard row applications.

Ensuring targeted exposure for plants. We project UV-C light onto grape leaves and clusters. Ensuring uniform treatment.

Environmentally friendly, efficient, precision, cost-effective. No chemicals, no resistance problems, better crop quality.

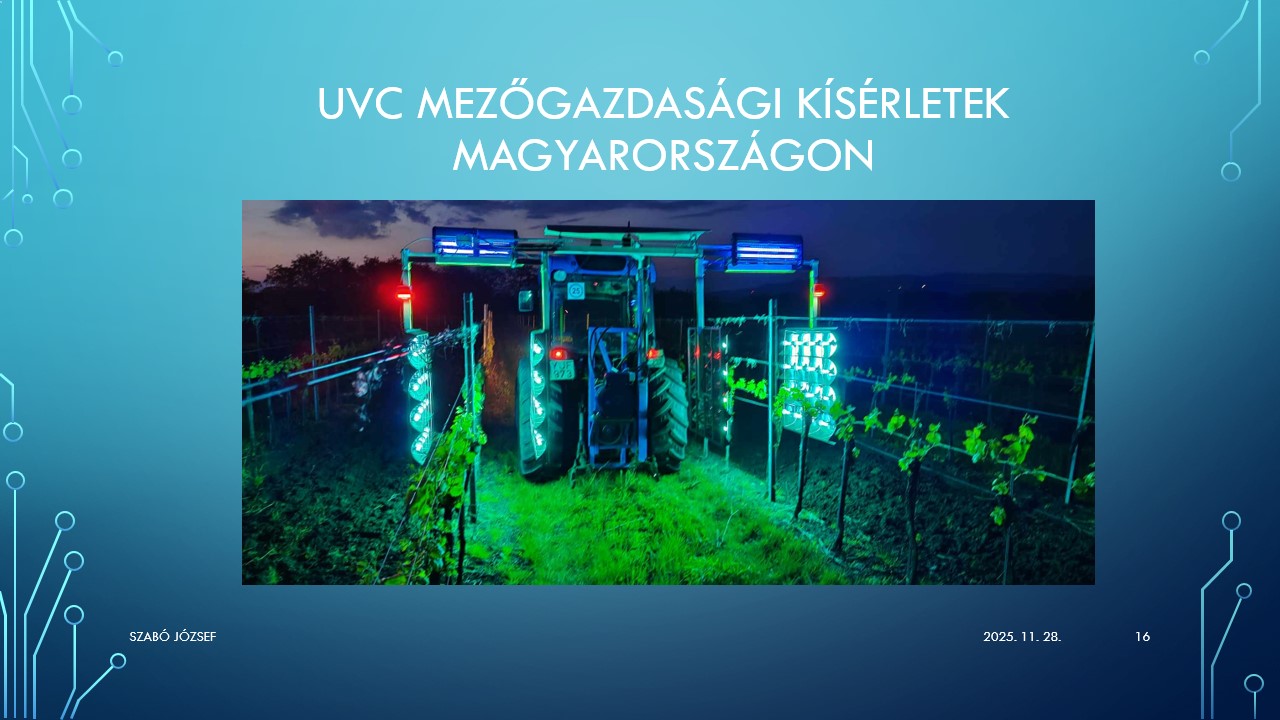

Szerencsés Winery has been applying the technology since March 2024. Excellent results: 85% powdery mildew reduction, outstanding wine quality.

The VitiRay team led by József Szabó develops the technology for local conditions. Besides brandy and essential oil production, crop protection is the main profile.

Involve 10 vineyards in the program. 50+ hectares of UV-C treated grapes. Successful harvests and excellent quality wine material.